Welcome to Qingdao Xiangtai Material&Energy Technology Co., Ltd.

Welcome to Qingdao Xiangtai Material&Energy Technology Co., Ltd.

Products

Products Hydrogen energy related equipm

Hydrogen energy related equipm

The hydrogen storage density per unit

volume of hydrogen storage alloy is much higher than that of high-pressure

bottled methods, also higher than that of liquid hydrogen.

The hydrogen storage conditions are stable,

and the hydrogen absorption and desorption process are accompanied with obvious

thermal effects, it has huge application potential in the field of energy

conversion and utilization.

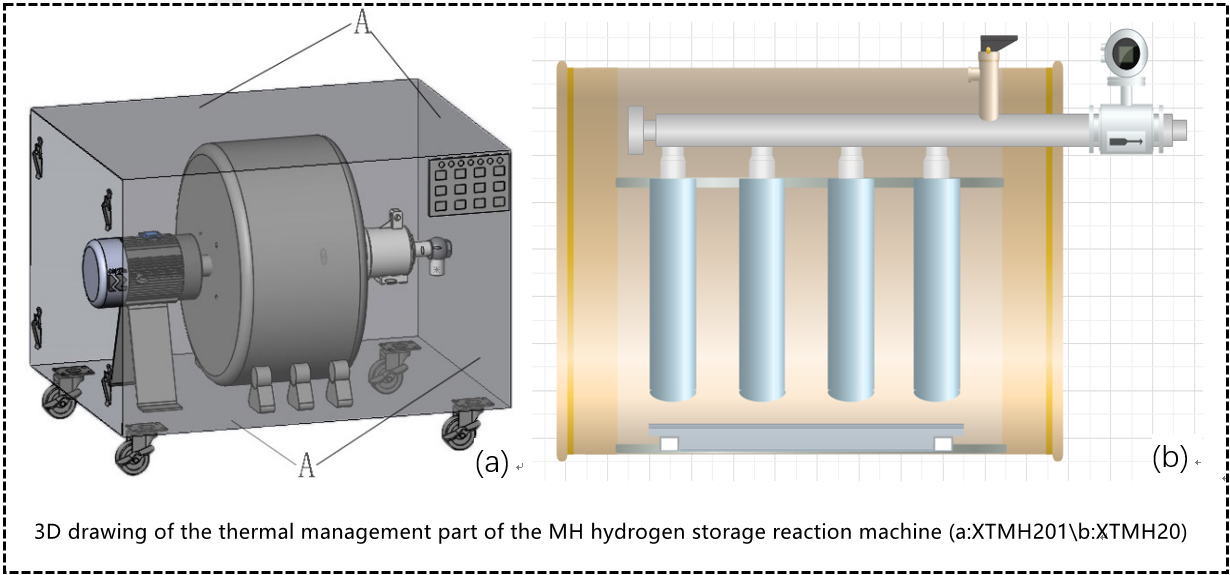

Regardless of whether MH is used as

hydrogen or a heat medium, its performance is mainly achieved in the reaction machine,

and is closely related to the process of MH absorption and desorption.

The MH absorption and desorption process

has a significant thermal effect and a pulverization effect caused by the

periodic expansion and contraction of the crystal lattice. Therefore, the

design of the reactor (reaction machine) in the MH hydrogen storage/heat

storage system and its heat exchange method, hydride filling method and so on

design is the kay for deciding the mass and heat transfer capacity of the

reaction machine (hydrogen absorption and desorption rate, heat exchange

capacity, hydrogen flow characteristics) and the key to long-term safety and

stability.

Because the hydrogen release process of

medium and high temperature MH alloys requires heat source to provide stable

starting heat, and the process of hydrogen release requires a cold source to

extract the reaction heat characteristics, we developed a series of light

weight MH Hydrogen storage reaction machine, that can be used for heat recovery

for medium and high temperature magnesium-based alloys.

Technical features:

1) The use of phase change materials with

heating devices can quickly respond to the process of hydrogen absorption and

desorption.

2) The system is independent, and the equipment

is highly integrated, without external auxiliary heat flow transmission

equipment.

3) Mixed with special carbon materials,

which can effectively weaken uneven stress distribution and ensure heat

transfer and gas flow.

4) It weakens the cyclic compression and

natural sinking effects produced by the hydrogen absorption and desorption

process of the static alloy reaction machine and has significant technical

advantages and safety and reliability.

5) The safe filling rate can achieve 50%.

The packing density of the hydrogen storage alloy in the machine is uniform and

stable, and the hydrogen storage density and the cost-effectiveness of the

reaction bed device are significantly improved.