Welcome to Qingdao Xiangtai Material&Energy Technology Co., Ltd.

Welcome to Qingdao Xiangtai Material&Energy Technology Co., Ltd.

Products

Products Purification technology and eq

Purification technology and eq

Purification technology and

equipment for multi-pollutants of ship exhaust based on EGC in-situ O3/NaClO

Maritime transportation undertakes more

than 90% of my country’s international trade transportation volume, and 90% of

commercial ships use heavy fuel oil, which emits a large amount of NOx

(~20g/kW•h), SOx (~22g/kW•h), PM (~0.8g/ kW•h), contributing rates to the

concentration of NOx, SO2, and PM10 in the ambient air of coastal areas,

especially port cities, are as high as 10%~30%, 15%~50%, and 5%~37%, ocean-going

vessels have become the primary atmosphere reason of pollution.

The International Maritime Organization

(IMO) announced the amendment to “the International Convention for the

Prevention of Pollution from Ships” (implemented on January 1st, 2020) based on

the resolution MEPC.277(70) on October 28th, 2016, it is urgent to reduce the

emission of air pollutants from ships.

In my country's latest ship air pollutant

control policy (Issued by the Maritime Safety Administration of the Ministry of

Communications [2018] No.168), marine fuel oil is more stringent than IMO

requirements.

In the future, green emission commercial ships

will present three mainstream response measures, that is, use low-sulfur ship

combustion, or install tail gas purification measures to use high-sulfur ship

combustion, or use alternative fuels (such as liquefied LNG).

In view of the large price difference

between low-sulfur ship fuel and high-sulfur ship fuel and the use of

alternative clean fuels requires a comprehensive power system retrofit, the

installation of exhaust gas purification measures has become the most

competitive development direction of ship exhaust gas purification.

At present, in terms of ship exhaust gas

aftertreatment technology, single pollutant control technology is mostly used

internationally, such as particle trap (DPF) to control PM, selective catalytic

reduction (SCR) to control NOx, and wet seawater scrubbing technology (EGC)

Control SO2, but the above-mentioned technical combination has problems such as

complex system, large number of equipment, large area, difficult layout, high

investment operation cost, etc.

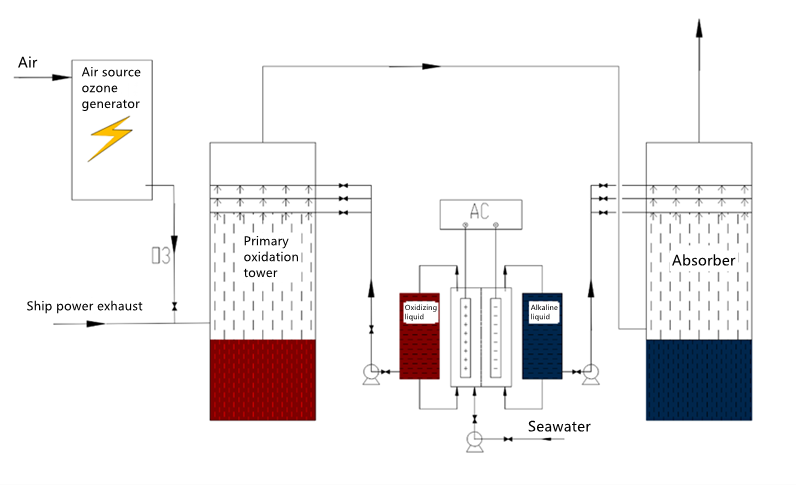

Therefore, combined with the development

trend of domestic and foreign ship exhaust gas treatment technology, it is

inevitable to realize the removal of multiple flue gas pollutants in the

limited space of ships. The EGC-based multi-pollutant collaborative control

technology developed by our company focuses on the three footholds of light

weight, high performance and stability of denitrification, sulfur removal and

dust removal equipment, to meet the development needs of green shipping.

Technical

features:

1)

O3/NaClO is prepared by in-situ air and seawater, no need to store desulfurizer

and denitrification reducing agent on board, and the operation is safe and

reliable.

2)

O3/NaClO synergistic oxidation of NO, electrolyte\seawater combined with

ex-situ stepwise absorption of NOx/SOx, low emission index for comprehensive

deep purification of flue gas with multiple pollutants.

3)

Flexibly adapt to the free switching working mode of the ship's power grid

load, and the system integration, reliability, flexibility, economy, and

environmental friendliness are significantly improved.

4)

Multi-purpose and multi-productive coupling, can simultaneously provide marine

protective gas and ship ballast water treatment agent, low comprehensive demand

for electric power, and great economic competitive advantage.