Welcome to Qingdao Xiangtai Material&Energy Technology Co., Ltd.

Welcome to Qingdao Xiangtai Material&Energy Technology Co., Ltd.

Products

Products Energy comprehensive utilizati

Energy comprehensive utilizati

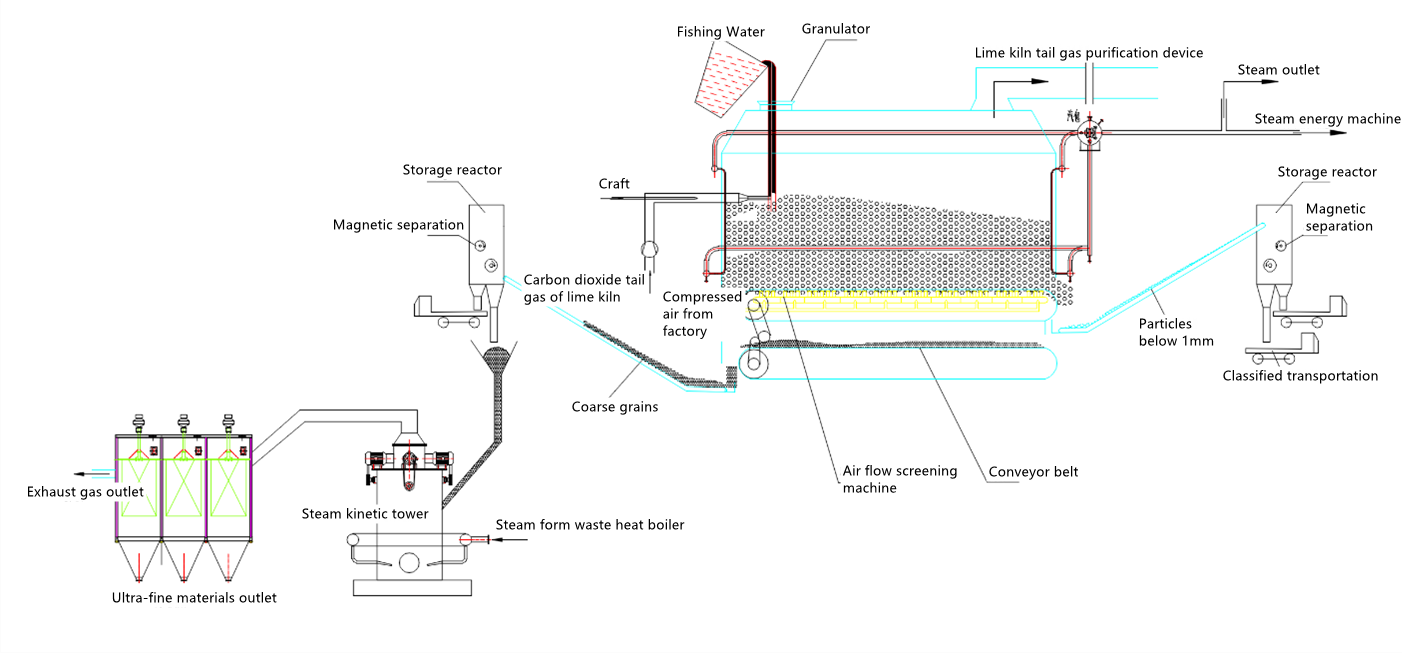

Our country mainly adopts the long-flow

converter steelmaking process, the converter steel slag accounts for 88% of the

total steel slag, the treatment process mainly adopts the water quenching

method, the environmental friendliness of the treatment process is low, the

iron and heat recovery effect is poor, and the degree of resource utilization

is unsatisfactory, its quantity increases about 120 million tons per month, a

large amount of storage or landfill destroys the ecological environment, and

environmental protection problems are serious, which seriously restricts the

iron and steel industry from achieving comprehensive green manufacturing.

The current prominent problems in the

resource utilization of converter slag are:

① converter slag contains free calcium

oxide (f-CaO) and free magnesium oxide (f-MgO), as well as trace amounts of FeS

and MnS. It is easy to form basic compounds when it meets water. It has poor

post-stability and volume stability when it used for cement material.

②the steel slag contains 20-30% FeOx

(calculated as Fe2O3) with basically no gelling activity, and the C3S and C2S

crystals are fully developed, with few defects, and poor gelling activity,

which makes the utilization rate improving.

③the iron-occurring phase in the steel slag

can be separated by weak magnetic field, and the proportion of metal iron and

magnetite is small, after iron removal, the total iron content of the steel

slag is still as high as 5-30%, and the grindability index is poor.

④melting steel slag contains a large amount

of heat energy (~1.2GJ in per ton slag, equal to the calorific value of 41kg

standard coal). The current treatment process mostly uses a large amount of

water medium to quench it, producing hot water or steam, and the heat medium is

low in heat (generally <100℃), and it contains lots of particulate impurities and suspended matter, which is taste badly and easily causes fouling of heat exchangers and conveying pipes. In fact, the overall heat recovery rate is very unsatisfactory.

Through in-depth research on the

"slag, iron, heat" characteristics of steel slag, we have formed a

converter slag gas-water quenching and alkali reduction magnetization heat

recovery technology.

Technical features:

1 The carbon fixation and alkali reduction

reaction of steel slag uses the steel mill's own lime kiln tail gas and

industrial water to form an atomized water-gas mixture to quickly quench the

molten steel slag, carbonation, and alkali reduction.

2 After the steel slag is de-alkalied and

modified, it is contacted with a limited amount of room temperature air, and

the secondary cooling is completed at the same time, and the FeO is

incompletely oxidized and converted into magnetite, the subsequent magnetic separation

helps to reduce the total iron content of the steel slag and increase the

grindability.

3 The radiant convection waste heat boiler

converts the calorific value of steel slag into high-temperature and

high-pressure steam, and the heat recovery rate is significantly improved, the

hot carrier gas after heat exchange still enters the existing lime kiln tail

gas purification equipment of the steel plant, which is extremely

environmentally friendly.

4 The quality of steel slag is weakly

alkaline, low RO phase, high C3S/C2S content and rich in high content of

amorphous components, with good stability and gelling activity.