Welcome to Qingdao Xiangtai Material&Energy Technology Co., Ltd.

Welcome to Qingdao Xiangtai Material&Energy Technology Co., Ltd.

Products

Products Ultra-low emission wet dust co

Ultra-low emission wet dust co

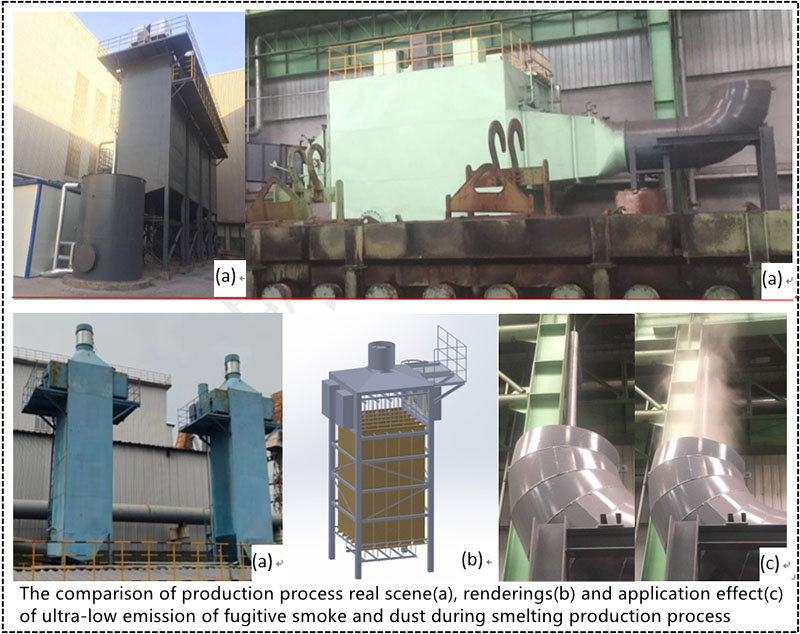

In response to the improving requirements

of environmental protection for the control of fugitive emissions, our company

has developed an industrial air purifier for fugitive emissions based on the

performance advantages of our free intellectual property technology—flexible

electrode wet electrostatic technology.

The industrial air purifier can deeply purify fugitive emission dust to achieve the purpose of air purification. The industrial dust collector can be widely used for: raw material storage yard, blast furnace ironmaking belt conveyor receiving point, steelmaking equipment, steel rolling production, cement industry, glass industry, ceramic industry, pouring industry and other key monitoring industries for unorganized emissions.

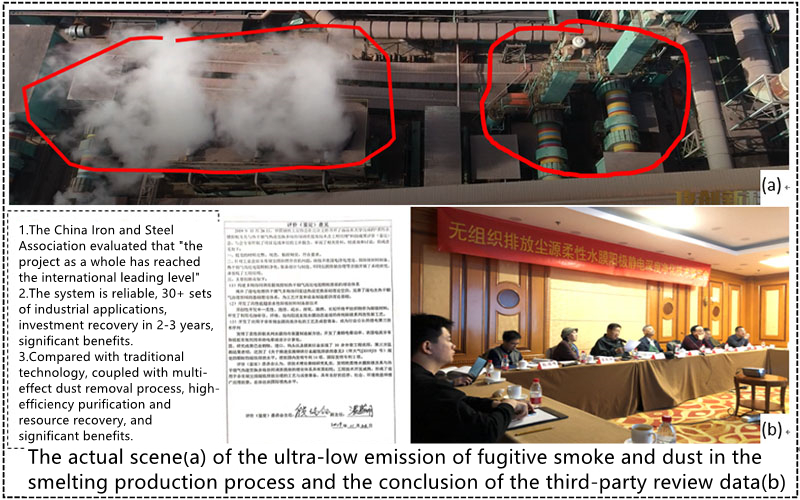

Changshu Longteng Special Steel Co., Ltd.

and Tangshan Yanshan Iron and Steel Co., Ltd., which apply this technology,

have successively started the treatment of dry flue gas emission during the

steel production process, successively in multiple processes such as casting,

digestion, mixing, rough rolling, finishing rolling, continuous casting and so

on process, the workshop has completed more than 30 sets of treatment

applications, and through third-party test, ultra-low emissions of <5mg/m3 have been achieved, with significant environmental, economic and social benefits.

During the implementation of the project, the company gained this environmental bonus and was awarded the title of "Ultra-low Emission Class A Enterprise". Peer evaluation believes that: the overall level has reached the international leading level.

Technical features:

1) It is installed on the top of the kiln and workshop and has the functions of dust collection and chimney at the same time, and the layout is flexible.

2) It is suitable for industrial production process including intermittent emission sources (such as ferrosilicon casting, cast pipe, blast furnace tapping, raw material accumulation, transportation, spraying, etc.) large amount of unorganized emission dust control.

3) Low resistance, high equipment efficiency and reliable system.

4) Under the condition of low water

consumption, uniform water film washing, and ash cleaning are adopted, and the

process of gradual separation of ash and water to clean slurry is adopted to

realize the resource utilization of the collected solid particles.

Previous:No Information

Next:Ultra-low emission wet dust collector technology for converter gas soot