Welcome to Qingdao Xiangtai Material&Energy Technology Co., Ltd.

Welcome to Qingdao Xiangtai Material&Energy Technology Co., Ltd.

Products

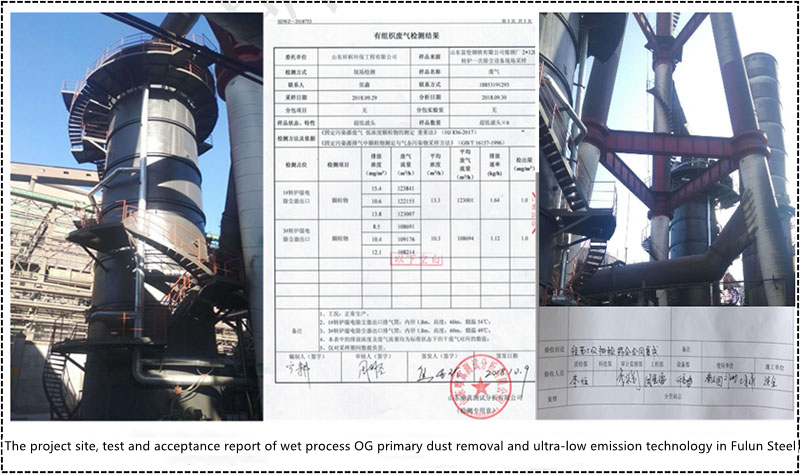

Products Ultra-low emission wet dust co

Ultra-low emission wet dust co

At present, about 60% of the domestic

converter gas dust removal adopt OG wet process, and the OG wet dust removal

outlet particle concentration is 30-60mg/Nm3.

With the improvement of environmental

protection standards, the original OG wet dust removal cannot meet the emission

standards, needing upgrading and retrofit gradually.

At present, the general solution for

achieving ultra-low emissions of converter gas is to adopt dry electrostatic

dust removal technology, while the solution of transforming OG wet dust removal

into dry dust removal faces problems such as high difficulty, high investment,

and long construction period.

In order to promote the application of

high-efficiency, reliable and ultra-low emission wet electrostatic

precipitators to the converter gas wet dust removal field, our company has conducted

in-depth research on converter operating conditions, gas composition, converter

gas recovery, discharge operation systems and so on problems, and achieved the

safe and reliable application of wet electrostatic precipitator in converter

gas OG wet dust removal.

Technical features:

※ The operation of the device is safe,

stable and reliable, and can replace similar foreign technology products.

※ Solved the problem of explosion venting

of converter gas in wet electrostatic precipitator.

※ The wet electrostatic precipitator is

arranged after the gas recovery three-way valve, and the arrangement is

flexible, making little changes to the existing system, and will not affect the

operation of the existing system;

※ Solve the problem of meeting the emission

standard of gas, and the concentration of emission particulate matter can be

lower than 5mg/Nm3.

※ The device is automatically matched with

the converter operation, which can be fully automatic and unattended operation;

※ The investment is less, the construction

period is short, and the interface time when the furnace shutdown only takes 3

to 5 days.

Previous:Ultra-low emission technology for unorganized emission control of scattered smok

Next:No Information