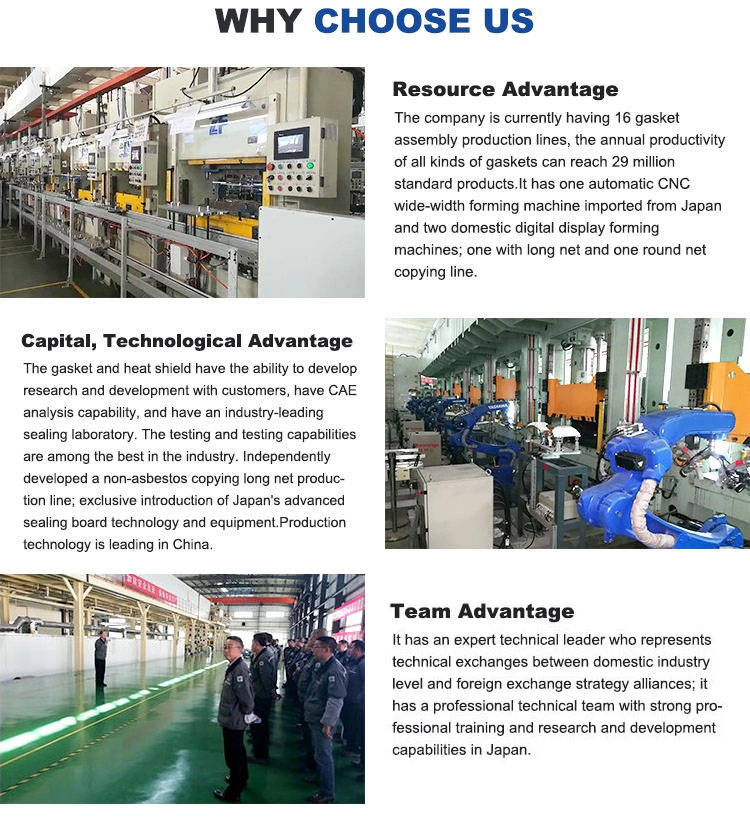

Welcome to Qingdao Xiangtai Material&Energy Technology Co., Ltd.

Welcome to Qingdao Xiangtai Material&Energy Technology Co., Ltd.

Products

Products Non-asbestos fiberboard series

Non-asbestos fiberboard series

Aramid fiber, carbon fiber, fiberglass, etc. as a skeleton material, oil-resistant adhesive special cooperation, add the corresponding chemical additives, fillers, the use of roller pressure legal system.

Features

* The maximum operating temperature is 300 degreesCand the maximum operatingpressure is 3.0MPa

* Good temperature, pressure resistance and durability

* Surface treatments such as anti-stick can be carried out

* The EU ROHS certification and asbestos-free confirmation have been made

* Can be made wire mesh, plate-enhanced asbestos-free sealing plate

Product Use

Mainly used in machinery, petrochemicals, automobiles, motorcycles and other conditions for sealing padding materials, especially suitable for automobiles, motorcycle engines with gaskets. Suitable for a variety of oil, air, water, steam and other media.

Product specifications

Wide × (mm):1500×4500, 1500×1500

Depth (mm):0.3 to 3.0

Special specifications can be agreed with the customer

Physical performance

|

The item |

Refers to the target |

|

| Lateral stretch strength Mpa |

≥10 。 |

|

| Density g/cm3 |

1.8±0.15 。 |

|

| Burn loss (550 degreesC×1h). % |

≤40 。 |

|

| Creep relaxation rate (100degrees C×22h). % |

≤30 。 |

|

| Compression rate % |

10±5 。 |

|

| Bounce rate % |

≥45 。 |

|

|

IRM903 . . . standard oil 150°C×5h 。 |

The rate of thickness change % |

≤15 。 |

| Weight change rate % |

≤15 。 |

|

| Horizontal stretch strength MPa |

≥7.0 。 |

|

|

ASTM Fuel B The temperature ×5h |

The rate of thickness change % |

≤15 。 |

| Weight change rate % |

≤15 。 |

|

|

Water: glycol s1:1 100°C×5h 。 |

The rate of thickness change % |

≤15 。 |

| Weight change rate % |

≤15 。 |

|

| Compression rate % |

15±5 。 |

|

| Bounce rate % |

≥35 。 |

|

|

Nitrogen leakage rate (Q/YSM BJS001-2009) ml/min |

≤1.0 。 |

|

The maximum temperature and maximum pressure cannot be used at the same time.

These are general guidelines and should not be used as the only way to select or exclude the material